FXD16/2XZ-4B

1. Features of FXD series products:

The FXD series vacuum pump is a two-stage directly connected rotary vane vacuum pump developed by our company recently. The pump adopts internationally advanced technology, and there are no sealing parts in the pump body (thereby extending the service life of the pump). Each spare part in the pump body is marked with the logo of Foster and arranged in sequence. Customers can complete the loading and unloading of the pump body within 15 minutes based on the sorting on the spare parts.

In addition, the unique design of the exhaust port can achieve 100% anti fuel injection.

The FXD series of products further extends the service life of the pump, greatly reducing the damage rate, and making the structure simpler, more reliable, and easier to assemble and repair.

2. FXD Product Overview:

The FXD (2XZ) rotary vane vacuum pump is a dual stage direct connection structure, and its working performance consists of two parts: a high-pressure stage and a low-pressure stage. Its suction port is connected to the vacuum equipment, which sucks in and out a large amount of the container during operation. When the equipment obtains vacuum, the high-pressure stage exhaust valve plate will be closed, and the gas sucked in by the high-pressure stage will be transferred to the second stage, and a certain vacuum can be obtained through the second stage suction and discharge vacuum equipment. The technical parameters of the rotary vane vacuum pump are 4X10-2 pump connected to the motor, with high rotational speed, small appearance, compact structure, and convenient flowability. It is specially designed with metal scraper blades, suitable for the front stage pump of diffusion pumps, precision instrument matching and use rooms, pharmaceutical, food packaging, electronics and other units.

3. Purpose and Scope of Use

The FXD (2XZ) type direct connected vacuum pump is a basic equipment used to extract gas from sealed containers and obtain vacuum. It can be used alone, or as the front pump of Booster pump, diffusion pump, molecular pump, etc. It can pump out general gas, or mixed gas containing a small amount of condensable gas. The pump can be used in vacuum smelting, vacuum welding, vacuum drying, Vacuum packing, Vacuum distillation, vacuum degassing, electric vacuum, experimental instruments and equipment, vacuum operation, refrigeration equipment, air-conditioning, refrigerator, color TV production line, etc

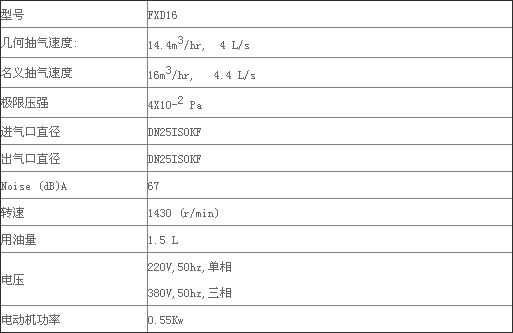

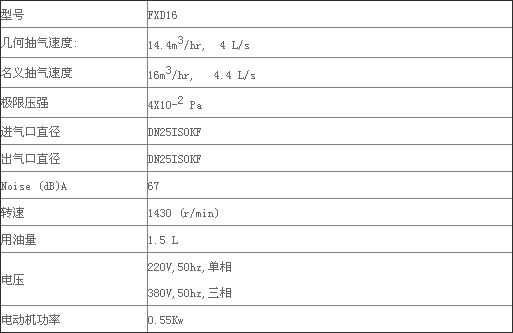

4. Technical parameters:

Brand: Foster (focusing on the production and research and development of vacuum pumps in 2017)

Model: FXD16

Packaging: Standard wooden box packaging

Gross weight: 35kg (220V) 32kg (380V)

Recommended oil model: Huifeng A200

Product photos are as follows:

Note: (1) The pressure is the measured value of a mercury compressed vacuum gauge (Maxwell gauge)

(2) The measured value of a resistance or thermocouple vacuum gauge for good total pressure

5. Operating instructions:

1. Check the oil level and fill it to the center of the oil gauge when the pump is stopped. If it is too low, the exhaust valve cannot function as an oil seal, which affects the vacuum degree. If it is too high, it may cause fuel injection during atmospheric starting. It is normal for the oil level to increase during operation. Oil extraction

Add clean vacuum pump oil of the specified brand through the oil filling hole. After refueling, the screw plug should be screwed on. The oil should be filtered to prevent debris from entering and blocking the oil hole.

2. The FXD (2XZ) rotary vane vacuum pump can be started at once under atmospheric conditions or any vacuum degree. If an electromagnetic valve is installed at the pump port, it should act simultaneously with the pump.

When the ambient temperature is too high, the temperature of the oil increases, the viscosity decreases, and the saturated vapor pressure increases, which can cause a decrease in good vacuum, especially the total pressure measured using a thermocouple. If ventilation and heat dissipation are strengthened or pump oil performance is improved, good vacuum can be improved.

4. Check the good vacuum of the rotary vane vacuum pump based on the compressed mercury vacuum gauge. If the gauge has been fully pre drawn and calibrated, the pump temperature reaches stability, and the pump port is directly connected to the gauge. Within 30 minutes of operation, a good vacuum will be achieved. The value measured by the total pressure gauge is related to the error of the pump oil, vacuum gauge, and gauge, and sometimes the error can be even large, which can only be used as a reference.

5. If the relative humidity is high or the extracted gas contains a lot of condensable steam, it is advisable to open the gas ballast valve after connecting the extracted container, and close the gas ballast valve after running for 20-40 minutes. Before stopping the pump, the gas ballast valve can be opened to move without load for 30 minutes to extend the service life of the pump oil

6. Selection of oil for FXD (2XZ) rotary vane vacuum pump: The viscosity of the pump oil affects the starting power and good vacuum of the pump. When the viscosity is high, it is beneficial for the vacuum degree, while the starting power is higher. The saturated vapor pressure of oil at pump temperature will affect the overall pressure of the pump, and the lower the better.

(1) We recommend using Huifeng brand HFV-200 (2L and 4L pumps), HFV-200S (8L and 15L)

(2) If the requirement for vacuum is not high, and the oil is frequently contaminated and replaced, making it difficult to supply vacuum pump oil, 50 # mechanical oil can be used instead.

(3) If the ambient temperature is low, it is difficult to start, and the requirements for good vacuum are not high, real pump oil or mechanical oil FX (2XZ) rotary vane vacuum pump with slightly lower viscosity can be used for maintenance and upkeep.

6. Precautions:

1. Ensure the cleanliness of the FXD (2XZ) rotary vane vacuum pump to prevent debris from entering the pump.

2. Maintain the oil level of the FXD (2XZ) rotary vane vacuum pump.

3. When water or other volatile substances enter the pump during storage and affect the vacuum, the gas ballast valve can be opened to purify it, and the vacuum recovery situation can be observed. If it is ineffective for several hours, the pump oil should be replaced, and if necessary, it can be replaced again. Oil change method: Run the pump for about half an hour to make the oil thinner. Stop the pump and drain the oil from the oil drain hole, then open the air inlet and run for 10-20 seconds. During this time, slowly add a small amount of clean pump oil from the suction port to replace the oil in the pump chamber. If the oil coming out is dirty, the latter can be repeated

9. Foster Quality Service Commitment:

1. Quality standards: The products are strictly produced and inspected in accordance with national standards

2. Standard equipment: The product is equipped with an inspection certificate, warranty card, and user manual.

3. Product quality maintenance: The product is guaranteed for one year from the time of shipment.

4. Packaging standard: Standard wooden box packaging.

5. Technical support and consultation: Our company provides 24-hour hotline consultation service: 4006-1818-25

沪公网安备 31011802002620号

沪公网安备 31011802002620号