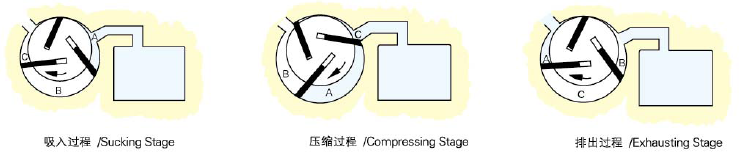

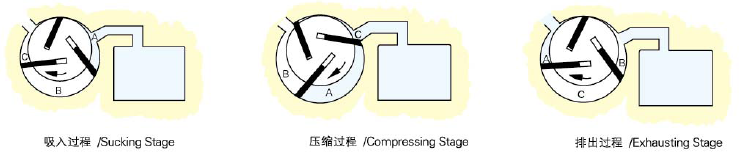

一、真空原理:

In the circular pump body (stator) with suction and exhaust valves, there are three blades with an eccentric rotor moving by centrifugal force in the rotor slot. These blades separate the pump into three parts, and their volume changes periodically with the rotation of the rotor, completing the process of gas suction, compression, and elimination, thereby causing the gas at the suction port to be sucked, forming a vacuum.

2、 Vacuum pump performance:

*Good vacuum, can be less than 0.5 millibar

*High pumping speed

*Low working noise, can be less than 62 decibels

*Strong steam extraction ability

*Environmentally friendly, the pump is equipped with an oil mist eliminator that can remove 99.99% of the oil in the discharged gas

*Compact structure, scientifically reasonable design, lightweight, and easy to install in industrial systems

3、 Application scope:

1. Packaging and pasting

Vacuum or inert gas packaging for various foods, metal parts, and electronic components

Paste photos and advertising paper

2. Lifting, conveying, suction, loading and unloading

Lifting of glass panels

Holding of wooden and plastic boards

Loading and unloading of non magnetic components

Loading, unloading, and conveying of paper and paperboard in the paper and printing industry

Conveying of powdered materials

3. Drying, degassing, impregnation

Drying and impregnation of electronic components

Degassing of molds, coatings, and vacuum furnaces

4. Other

Laboratory equipment

Medical devices

Recovery of Freon

Vacuum heat treatment

沪公网安备 31011802002620号

沪公网安备 31011802002620号